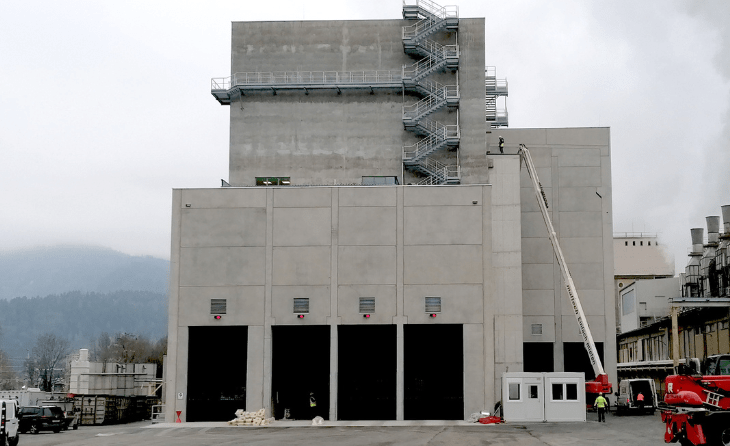

REDWAVE, the leading company in recycling technology from the Green Tech Valley, has recently supplied a refuse derived fuel processing plant for the Norske Skog paper mill in Bruck. This will allow residues, from the material recycling sorting plants, to be utilised and burned as a substitute fuel at the mill. This represents a total investment of €72 million. It is intended that the power plant will cover two thirds of the heating requirement and one third of the electrical energy requirement at the site.

Green technologies for sustainable energy production

The support provided to Norske Skog by REDWAVE with this project included planning, supply and commissioning of the entire plant, including electrical measurement, control and regulation technology. This enables processing of substitute fuels, which are mainly obtained from bulk industrial and commercial waste or, as in this case, sorting residues from recycling plants. As a result, the use of primary raw materials such as coal and gas can be dispensed with. Less waste ends up in landfill, renewable energy is used and resources conserved.

REDWAVE Qi - New technology for material analysis and control

Processing of the refuse derived fuel (RDF) in the new facility, prior to incineration, is designed to maintain high quality and purity. This is critical for optimum and efficient use of the energy contained in the waste material. The required high material quality is ensured through fully automatic analysis of the processed substitute fuel using the new REDWAVE Qi analysis and control system. This allows analysis of the material at high speed, providing key information about calorific and heating values or information on moisture content. The data is output online via the REDWAVE mate software. The data on material composition also includes details of the chlorine values of the RDF and statements about the quality of the purchased input material. This allows comparison in measurements to be made, for example, with values from the combustion or the chlorine analysis in the laboratory.