EU SYMPHONY project

JOANNEUM RESEARCH is coordinating the EU SYMPHONY project (Smart Hybrid Multimodal Printed Harvesting of Energy) with the aim of developing a power supply platform to supply power to wireless sensor nodes. Such sensor nodes are often sited in problematic or inaccessible locations, making cabling impossible. The focus is not just on the potential for autonomous power systems, but also how to make them sustainable.

In contemporary daily life, we are surrounded by a multitude of sensors. These sensors are often hidden or secreted away, for example embedded in walls of houses, in the body of a vehicle or high up in wind turbines. This raises the question of how such wireless and inaccessible sensors can be supplied with power in a sustainable manner.

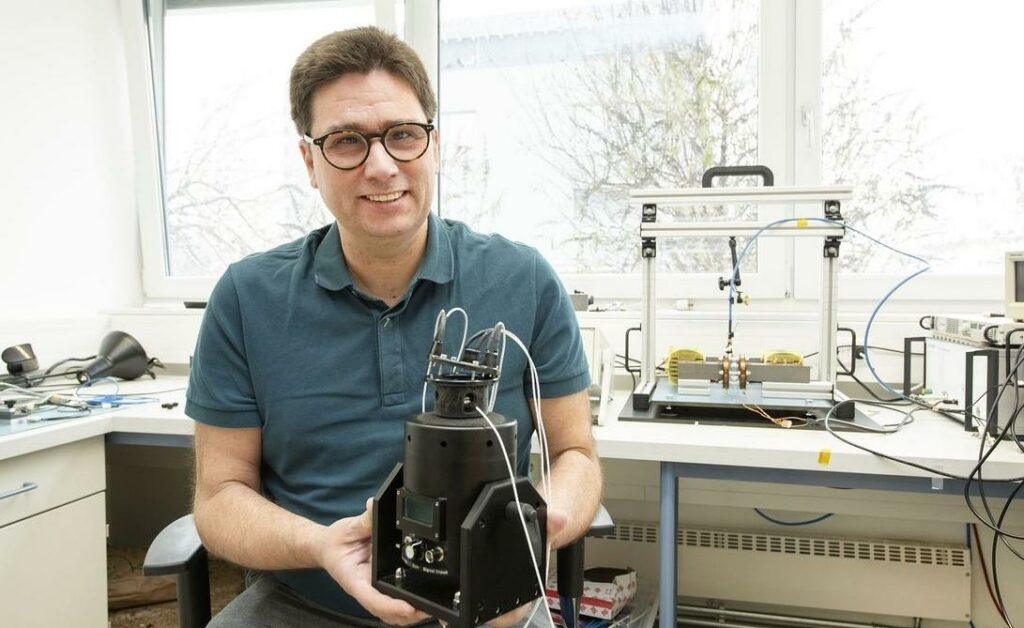

How much power is actually required by such a small, built-in sensor, for example, to provide information about room temperature? According to Jonas Groten, the expert for piezoelectric energy harvesting at MATERIALS, the Institute for Surface Technologies and Photonics at JOANNEUM RESEARCH: “A sensor requires 0.1 to 10 milliwatts under permanent wireless transmission conditions”.

Converting kinetic energy into electrical power

“We asked ourselves how we can most efficiently guarantee a permanent autonomous power supply in hidden places,” explains Jonas Groten. “One option is to convert kinetic energy, such as vibration or rotation of machinery, into electrical energy. Thus, non-electrical energy becomes electrical energy and can then be harvested directly in-situ at the specific location. This in essence is the energy harvesting system and it functions in many applications”. The most well-know and already mature technology is that of photovoltaic cells. But that only works with light. Vibrations are a very attractive alternative.

You can use the kinetic energy of machines that “shake” on the production line, for example. For this you require a material with electromechanical properties that acts as a converter. This is where lead compounds are often utilised, but they are very toxic. “For this reason, we are using a lead-free polymer with piezoelectric properties”, elaborates Jonas Groten further. “This polymer has several advantages: It is not toxic, it is cheap, and it can be printed over large surfaces. Our research is concerned with how we can further improve this material.”

Examples of applications

Within SYMPHONY, three example applications for the energy-converting polymer are currently being investigated: condition monitoring in a wind turbine, energy-efficient room heating/cooling in a smart house and pressure monitoring of inner tubes on (e-)bicycles.

How exactly does the conversion of energy work in the polymer? Researchers at MATERIALS, have been working with the piezoelectric polymer PVDF for more than ten years. Under certain conditions, this polymer forms a structure whereby the smallest molecular dipoles add up over a large area. We refer to this as a remanent polarisation. If the polymer is now deformed, this polarisation changes, together with the number of electrical charges in electrodes applied to (printed on) the polymer. If these electrodes are connected, mechanical deformation produces electricity that is then used for power generation.

Energy harvesting represents a critical contribution to the fight against climate change. In essence, summarises Jonas Groten, “If we succeed in saving energy in the mobility, power generation, home and domestic heating sectors, i.e., the big generators of CO2 emissions, we will have taken an important step towards successfully fighting climate change”.