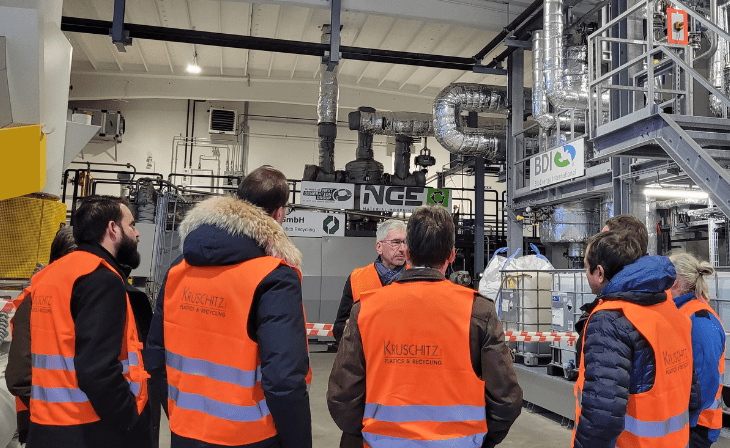

The company visit to SynCycle Operations GmbH in Kühnsdorf took place at the end of November. We welcomed numerous guests from Styria, Carinthia and Upper Austria to gain an insight into the innovative world of plastics recycling.

SynCycle Operations GmbH, a pioneer in the plastics recycling industry in Carinthia, gave an impressive demonstration of how valuable oil is extracted from plastic waste. This process is not only a milestone in waste recycling, but also marks an important step towards a more sustainable future. Pyrolysis technology involves heating the source material to around 500°C. During this process, the resulting gas is passed through two condensation stages and cooled, resulting in the formation of two oil fractions and one gas fraction. The gas, which makes up around 10-20% of the total output, is to be used in a gas turbine in the future. The two oil fractions, which make up around 65-80% of the input material, can be further processed as raw materials in the plastics industry. The remaining, unreacted solid material, known as “purge”, makes up around 10-15% of the total material, depending on the source material. The pyrolysis technology from Next Generation Elements GmbH is characterized not only by its impressive efficiency, but also by its modularity. This modularity makes it possible to adapt the technology flexibly to different requirements and locations.