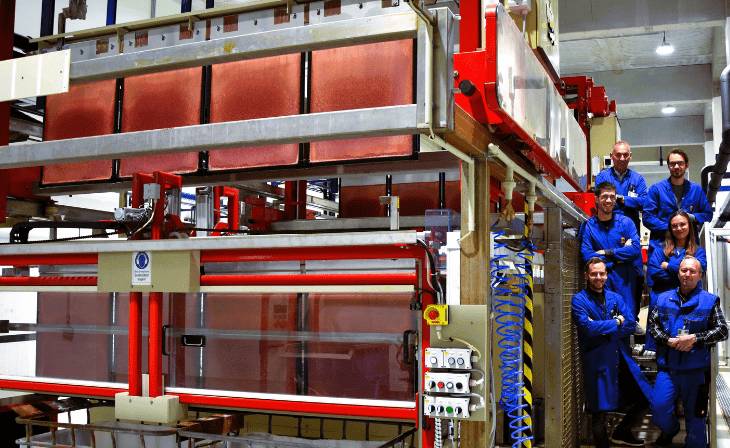

“AT&S aims to play a leading role not only in technology but also in the sustainable use of resources. Our progress over the past year shows that we are well on our way to achieving this goal. The new copper recycling plant in Leoben will soon enable the recovery of up to 1,000 kg of pure copper per day as well as the recycling of a considerable amount of chemicals. Efficient recovery processes are able to drastically reduce the amount of industrial sludge that is generated during production and has to be processed. In addition, the pollution of waste water is significantly reduced. Reusing these important resources protects both the environment and our budget,” says AT&S CTO Peter Griehsnig.

Running the recycling process on site has a number of significant advantages. In addition to the copper, valuable chemicals can be recovered and fed directly back into the production process. Compared to external recycling, this approach saves around 29% CO2. As part of the copper recycling project, AT&S has registered eight new patents, six of which have already been granted. The recycling system is an in-house development by AT&S in collaboration with the University of Leoben, which was recognized by the customer Airbus with the supplier award for the best improvement project in 2023. As soon as the fine-tuning of the copper recycling system in Hinterberg has been completed, AT&S will begin evaluating the introduction of similar systems at other production sites worldwide.

More than just recycling

Also last year, a process was implemented at the AT&S site in Nanjangud, India, which allows the recovery of copper and chemicals from used etchant. This system is also already running successfully and promises the recovery of up to 35 kilograms of copper per hour.

For the new plant in Kulim, Malaysia, all processes were already optimized during the planning phase in order to avoid the use of fossil fuels. The electricity requirements will also soon be met entirely from renewable sources. This means that AT&S’s goal of operating without fossil fuels from 2030 is within reach.

“We have set ourselves ambitious targets for the coming years. We already cover almost 62% of our energy requirements from renewable sources and have set ourselves the target of increasing this rate to 80% by 2025. Only if we implement our efficiency measures globally and further reduce our ecological footprint can our products fulfill their potential as the basic building blocks of a green and digital economy of the future,” says Marina Hornasek-Metzl, Head of Corporate ESG at AT&S.

Queries:

AT & S Austria Technologie & Systemtechnik AG

Gerald Reischl – Vice President Corporate Communications

+43 3842 200 4252 or +43 664 8859 2452

g.reischl@ats.net