ATM Recyclingsystems GmbH

ATM stands for Arnold Technology for Metal Recycling, based on more than 80 years of experience. The company plans, produces and provides worldwide service support for metal recycling systems for the treatment of secondary raw materials.

ATM Recyclingsystems has longtime know-how in the fields of engineering and production of metal recycling systems and offers worldwide service and wear parts support. The company plans and produces briquetting- and baling presses, scrap shears, shredders and sorting machines, among others. These characteristics make us a reliable partner for the recycling-, automotive- and process industry. Furthermore, the company offers innovative solutions in the field of digitisation and industry 4.0. A service app enables customers to easily review machine data via smartphone and to optimize processes. In line with the concept of predictive maintenance, machines can thereby be maintained proactively and economically. Depending on the customer's requirements, various digital service packages are available.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

ATM Recyclingsystems GmbH

Josef-Ressel-Gasse 8

8753 Fohnsdorf, Österreich

8753 Fohnsdorf, Österreich

Your Contact

Alexander Kügele

Cast iron breaker

Arno®Break is available in two different sizes for the efficient processing of gear housings, engine blocks and other cast iron scrap.

Cast iron breakers are available in two different sizes for the efficient processing of gear housings, engine blocks and other cast iron scrap. The ArnoBreak C 400 is used mainly for light scrap.

Josef-Ressel-Gasse 8

8753 Fohnsdorf, Österreich

8753 Fohnsdorf, Österreich

Contact to your Solution

Office ATM Recyclingsystems

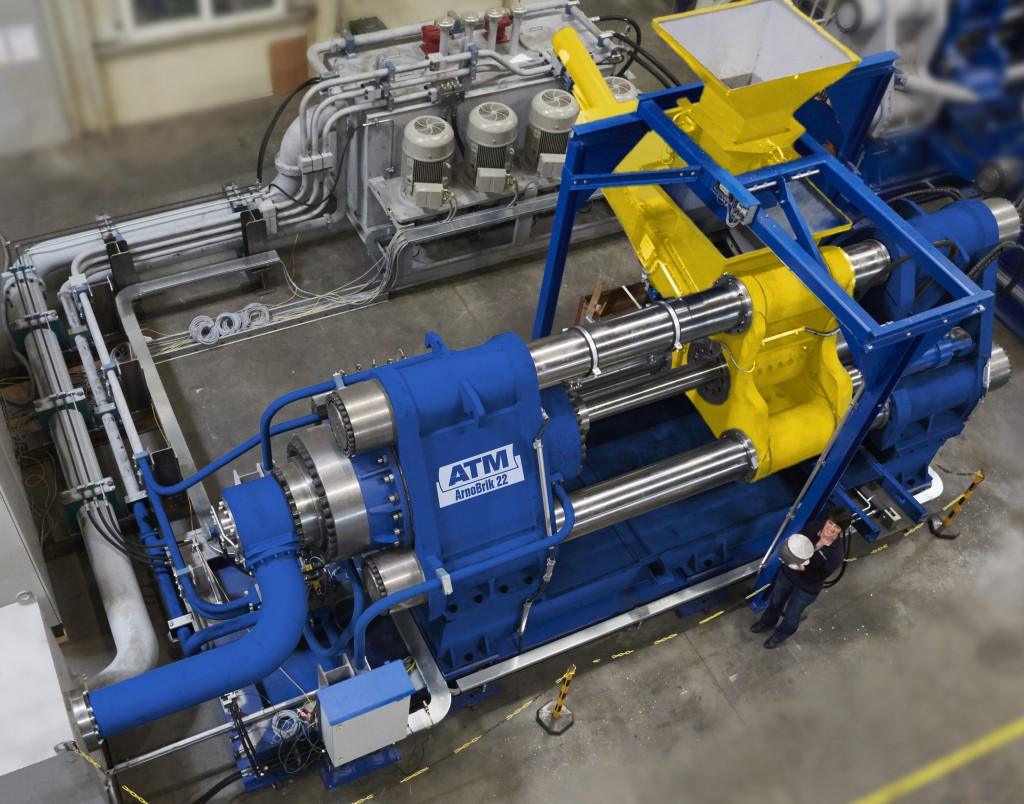

Briquetting Press

ArnoBrik Series Briquetting Presses create high-density briquettes out of loose swarf or metal chips, dust and grinding slurry.

Arno®Brik series briquetting presses are suitable for pressing and/or briquetting of all kinds of swarf resulting from machining of steel, cast iron, stainless steel, aluminium, magnesium, brass, copper, bronze, titanium, a.s.o. Also special alloys in powder form, slag compounds, battery waste and grinding sludge from a wide variety of materials can be processed, as well as tyre wires and mill scale.

Josef-Ressel-Gasse 8

8753 Fohnsdorf, Österreich

8753 Fohnsdorf, Österreich

Contact to your Solution

Office ATM Recyclingsystems

Baler Press

A baler press is used for baling metals sheets and profiles. Capacity from 1 to 35 tonnes per hour.

Arno®Press Baling Presses are suitable for compacting stamping press waste, such as steel, brass, copper and aluminium plates.

Josef-Ressel-Gasse 8

8753 Fohnsdorf, Österreich

8753 Fohnsdorf, Österreich

Contact to your Solution

Office ATM Recyclingsystems

Shredder

Arno®Shred machines are designed for shredding metals to resist the extreme conditions on scrap yards - suitable for ferrous and non-ferrous metal-swarf

Arno®Shred SS – the perfect choice for swarf shredding. The compact single-shaft shredder with the proven rotor-stator principle. Our single-shaft shredder guarantees problem-free operation by reliable technology.

The proven SS series are machines of powerful single-shaft shredders, which are primarily used for crushing metal chips.

Through continuous development in collaboration with the industry, the Arno®Shred SS series ensures flawless operation.

Our single-shaft shredders are modularly configurable and tailored with cutting discs specifically for your material.

Also available:

Arno®Shred SSE (for metals)

Arno®Shred DS (double shaft shredder)

Arno®Shred QS (four-shaft shredder)

Josef-Ressel-Gasse 8

8753 Fohnsdorf, Österreich

8753 Fohnsdorf, Österreich

Contact to your Solution

Office ATM Recyclingsystems

Scrap Shear

Arno®Cut Series Scrap Shears are the best choice for pre-compacting and cutting of metal plates and components, car body parts and similar light- to medium weight scrap.

ArnoCut Series Scrap Shears are the best choice for pre-compacting and cutting of metal plates and components, car body parts and similar light- to medium weight scrap.

Even steel rails can be cut with special notch blades.

The machines are available in five sizes from 4,000 to 12,500 kN shear force. All compacting chamber wear plates are made of Hardox 450 up to Hardox 600 and guarantee highest quality and a long service life.

Cutting cycles are optimised by linear transducer systems in the cylinders. The need for an elaborate foundation is avoided thanks to the monobloc construction. A centralized lubrication system, various clogging indicators and fault analysis guarantee simple maintenance. Comfortable operation with two joysticks and a multifunctional display in a soundproof, airconditioned cab make the scrap shear a workplace with the highest level of safety and productivity.

Josef-Ressel-Gasse 8

8753 Fohnsdorf, Österreich

8753 Fohnsdorf, Österreich

Contact to your Solution

Office ATM Recyclingsystems

Sieve drum

Arno®Sort sieve drum prepares metal swarf for high quality briquettes.

Arno®Sort sieve drum- preparing swarf for highest quality briquettes.

Sophisticated sorting technology can add the highest value to any recycling process.

It reduces the energy consumption of the shredder process to a minimum and improves the material quality.

The power consumption can be reduced down to 100 kW with an additional sorting process, considered a shredder capacity of 10 tons swarf per hour. Additional wear costs caused by tramp material are reduced by up to 10 Euros per tonne. The resulting improved briquette quality and a possible de-oiling increase the value of the briquettes even more.

Josef-Ressel-Gasse 8

8753 Fohnsdorf, Österreich

8753 Fohnsdorf, Österreich

Contact to your Solution

Office ATM Recyclingsystems