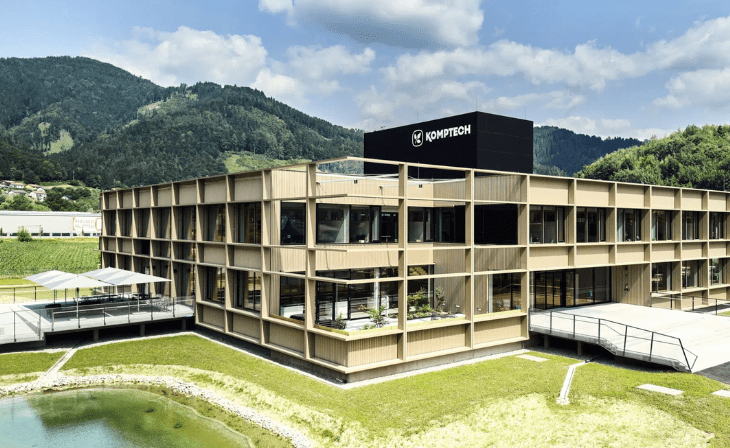

Komptech’s future is unfolding across 3,500 square meters in Frohnleiten: the Styrian recycling pioneer will soon be consolidating its key departments at its new headquarters north of Graz, directly adjacent to the existing buildings and the Komptech Academy for apprentice training, which are also being modernized. At more than €20 million, it is the largest infrastructure project undertaken by the company, which was founded in 1992. According to CEO Christoph Feyerer, the new building is a “beacon” not only because of the size of the investment: “It was clear to us from the outset that a major project like this is only sustainable if it is ecologically sound – from the foundations to the energy supply. Industry has a responsibility that we are consciously facing up to. With every planning decision, we examined whether there was a more environmentally friendly solution – and ultimately implemented it.”

Specifically, this means that recycled materials and innovative building materials are replacing conventional concrete in several areas, thereby reducing the ecological footprint. Instead of the usual XPS insulation boards, foam glass fill is used in the ground—a lightweight building material made from ground-up waste glass, the production of which generates only half as much CO₂ as conventional solutions. The energy concept relies on a combination of district heating from the neighboring Mayr-Melnhof industrial plants and air heat pumps. It is supplemented by a powerful 140 kWp photovoltaic system that generates renewable energy directly on site. The new Komptech headquarters is thus part of an exclusive group of office buildings that meet the requirements of the “klimaaktiv” standard in gold. A total of 85% of the CO₂ emissions that would be generated during the building’s life cycle have been reduced or completely avoided through structural and technical measures.

Styrian heart of Seoul’s waste management

“This is particularly remarkable as it is one of the most modern plants for processing substitute fuel. The finer and more uniformly the material is processed, the better the energy yield – and the lower the CO₂ emissions and wear and tear on the plant,” explains Konrad.

[Source: https://www.komptech.com]