Thermo-A1 Bracket for Ventilated Façades – Efficient & Fire-Safe

Patented Thermo-A1 bracket cuts thermal bridges by up to 30 %, saves CO₂ and installation time, meets top fire safety standards – sustainable, modular, non-combustible, and made in Austria.

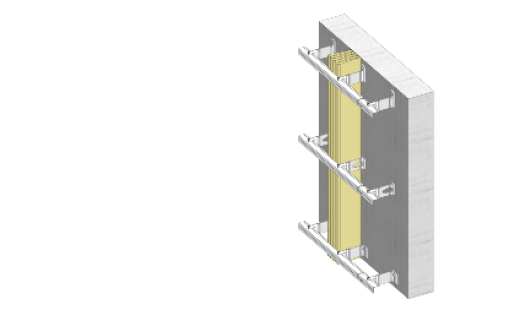

Konatec’s Thermo-A1 bracket is a globally unique substructure solution for ventilated façades, designed for maximum energy efficiency, safety, and installation ease.

Using an innovative, non-combustible composite, it reduces thermal bridges by up to 30 % compared to conventional aluminium or stainless steel brackets. This significantly lowers a building’s energy consumption, saves heating costs, and improves its CO₂ footprint.

Its statically optimised design requires far fewer brackets per square metre of façade. Fewer brackets mean reduced material usage, shorter construction times, and lower project costs. At the same time, the Thermo-A1 bracket offers up to ten times higher load-bearing capacity and meets the highest fire safety standards (Class A2 according to Austrian OIB regulations).

The modular “building block” system is highly adaptable: head and foot components are standardised, while the length of the mica profile is tailored to each project. Thermo-A1 brackets are available for both vertical (V-brackets) and horizontal (H-brackets) profiles and can be securely fixed to various substrates – concrete, brick, timber, and steel.

Combining sustainability, cost-effectiveness, and technical excellence, the Thermo-A1 bracket is ideal for new builds, renovations, and high-rise applications. It supports multiple UN Sustainable Development Goals (SDG 8, 9, 11) and, with different certificates it is suitable for international markets.

Villacher Straße 93 - 95

9800 Spittal / Drau, Österreich

9800 Spittal / Drau, Österreich

Contact to your Solution

Manuel Unterweger

Geschäftsführer und Co Gründer

Geschäftsführer und Co Gründer