ANDRITZ AG

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors.

The ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ AG

Statteggerstraße 18

8045 Graz, Österreich

8045 Graz, Österreich

Your Contact

Petra Wolf

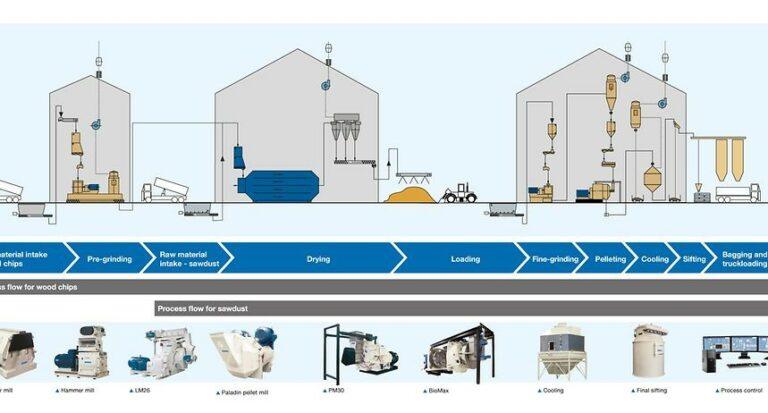

Biomass pelleting – Plant engineering

Systems, equipment, and services for the production of biomass pellets (wood fuel pelleting, pelleting of agricultural and industrial by-products)

Our business is based on meeting the requirements of forestry groups, energy companies, wood industries, and industrial as well as financial investors in biofuel pellet plants.

Leading supplier of biomass pelleting technologies:

With more than 350 reference plants worldwide, ANDRITZ is a clear global leader in biomass pelleting technology. ANDRITZ pellet mills produce more than 50% of all biofuel pellets produced worldwide and have held a market share of over 50% since the pioneering of biomass pelleting in the 1980s. We have the experience and know-how to cover your biomass pelleting needs.

Products:

- Hammer mills

- Air and dust filters

- Pellet mills – Biomass

- Conditioners

- Automation and process control

- Rotary valves

- Air density separator

- Pocket feeder

- Biomass Handling Systems

Contact to your Solution

Petra Wolf

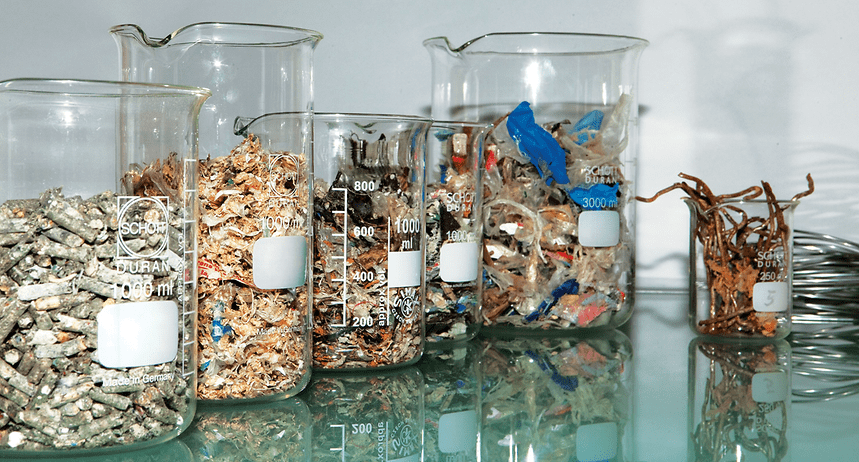

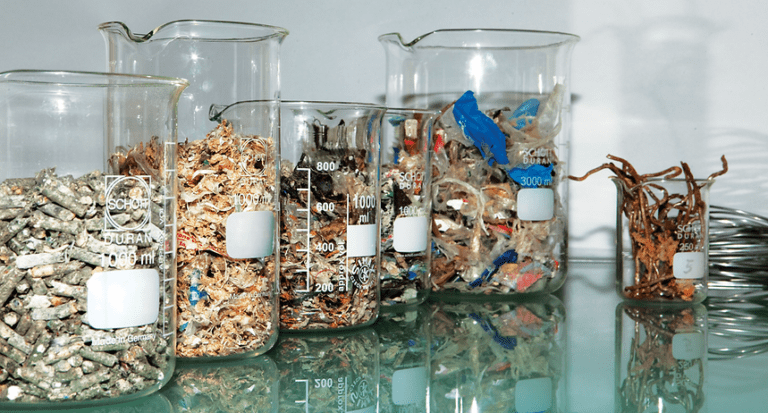

ANDRITZ Recycling Technology Center (ART Center)

The ART Center is open to recycling customers from almost all industries as well as to research and development facilities.

At the ART Center new materials, new machine configurations for diverse applications, new product designs and innovations are tested under real conditions with industrial-sized machines.

“We know how important it is to ensure continuous improvement in processes and products. At the ART centre, we therefore also offer our customers the opportunity to experiment with new machines and configurations as well as diverse materials, in order to find the very best solution for their respective requirements,” ANDRITZ Reject & Recycling Vice President Michael Waupotitsch, clarifies.

In the same building, Montan-University of Leoben has set up and is operating the digital waste research lab for testing the latest sensor technology.

Contact to your Solution

Petra Wolf

Thermal power

Turbogenerators, Boilers and Recovery Boilers

The major challenges facing energy producers today are to effectively utilize renewable fuel sources and to meet ever-tightening environmental regulations in a profitable manner.

ANDRITZ offers technologies for producing power from hydraulic applications and power from renewable fuels. The company’s knowledge of power production and steam generation draws upon 170 years of experience and numerous references worldwide.

ANDRITZ is a market leader in the hydropower business, offering a complete product portfolio including turbines, generators, and additional equipment for hydraulic power generation - from “water to wire” for small hydro applications up to more than 800 MW output. With more than 30,000 turbines installed, totalling 400,000 MW output, the company promotes hydropower as the most economical form of renewable energy, and supports its environmentally friendly concepts. The company also supplies turbogenerators for thermal power plants, with 991 installed totaling 94,500 MVA.

ANDRITZ also offers power generation systems for the efficient use of traditional fossil fuels as well as biomass, process gases, black liquor, and refuse-derived fuels. Auxiliary systems, including fuel feeding, ash handling, and air pollution control are part of the total offering. The company’s power portfolio comprises well-proven equipment such as circulating fluidized bed (CFB) boilers, bubbling fluidized bed (BFB) boilers, blast furnace gas (BFG) boilers, high-energy recovery boilers (HERB), sulfite boilers, sodium boilers, and gasifiers.

To enable compliance with environmental regulations, ANDRITZ also provides innovative air pollution control technologies, including wet flue gas cleaning, dry flue gas cleaning, DeNOx plants, and combined or multi-stage systems.

Experienced ANDRITZ project teams give you support during engineering, planning, erection, and start-up of your power generation system. Technical and service support is readily available throughout the life of the equipment.

Contact to your Solution

Petra Wolf

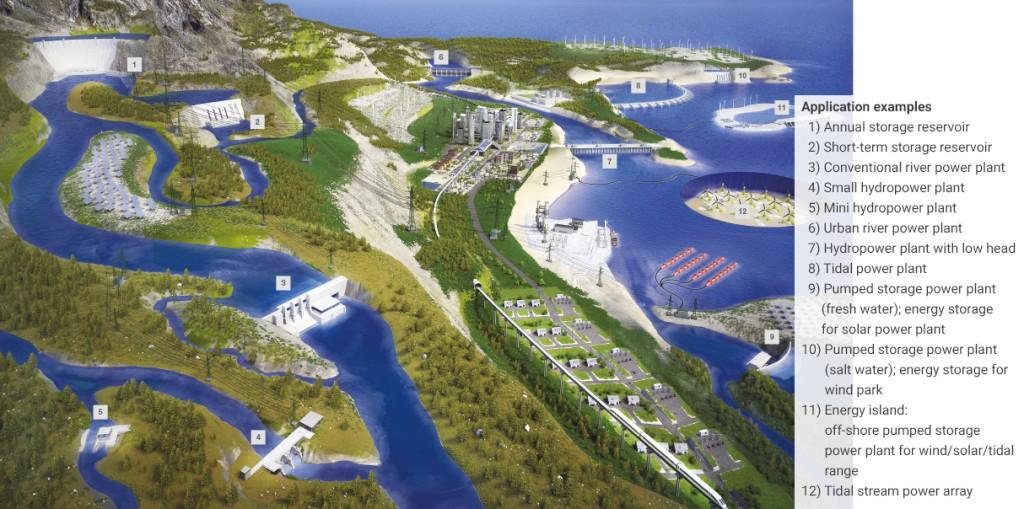

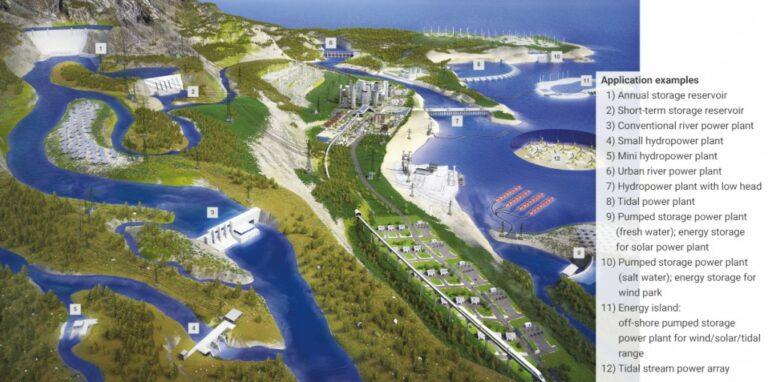

Hydropower plants

provides complete solutions for hydropower plants. Electromechanical equipment for hydropower stations, including turbines, generators, and additional equipment; modernization of existing hydropower stations, pumps (for water transport, irrigation)

Hydropower plants use the gravitational or kinetic energy of stored or flowing water to convert it into electricity.

Hydropower is the most widely used form of renewable energy. ANDRITZ HYDRO supplies turnkey tailor-made solutions for all kind of hydropower plants, from initial design to final commissioning – “from water-to-wire”.

Every hydropower location is different. Depending on net-head, water flow or storage capacity the erection of a hydropower plant requires careful planning and design as well as meticulous manufacturing and accurate installation of the technical equipment.

Types of hydropower plants

Run-of-river power plants

- Low head and medium/large flow

- Rivers with small or no reservoir, no large head change possible

- Francis, Kaplan and bulb turbines

- Base load power stations

Storage power plants

- High heads and medium flow

- Pelton turbines

- Peak load generation

Pumped storage power plants

- Using/pumping of wat-er between upper and lower reservoir

- Pump turbines

- Support for grid stability and peak load

Tidal power plants

- Using the ocean energy of tides

- Bulb turbines

Tidal current power plants

- Using the tidal current flow

Contact to your Solution

Petra Wolf

Waste-to-value systems

Innovative technologies for sludge and reject handling, material separation and recovery, and production of renewable energy help you reduce dependency on purchased power or fossil fuels and eliminate landfilling of waste.

Waste-to-value processes enhance your mill's profitability by recycling the mill waste products. Such processes are the source of renewable energy (gas and oil) and valuable by-products, such as aluminum and bio-char. Modular system designs with scalable sizes can be adapted to the waste streams. Furthermore, ANDRITZ supplies innovative technologies, processes, and equipment for the conversion of waste into valuable fuels. These systems include equipment for sludge and reject handling, drying, pelleting, and combustion – contributing towards recovering resources and closing the recycling loop.

Contact to your Solution

Petra Wolf

Recycling technologies

ANDRITZ recycling plants: profitable, efficient and reliable

The ANDRITZ plant range offers recycling solutions for a wide variety of different applications: Electronic and electrical waste, refrigerators, cable scrap, aluminum scrap, automotive parts like oil filters, motor blocks and tires, domestic, industrial and bio waste as well as rejects from the paper industry.

All materials contain valuable parts, e.g. copper, aluminum and iron, which are available and can again be sold as secondary raw materials when processed properly.

ANDRITZ Recycling technologies

Recover raw materials. Maintain values.

Innovative recycling technologies for material separation and recovery, treatment of various types of waste and rejects, and the production of renewable energy help you reduce dependency on purchased power and eliminate landfilling of waste - thus making substantial contributions towards protecting the environment.

ANDRITZ recycling plants: profitable, efficient and reliable

The ANDRITZ plant range offers recycling solutions for a wide variety of different applications: Electronic and electrical waste, refrigerators, cable scrap, aluminum scrap, automotive parts like oil filters, motor blocks and tires, domestic, industrial and bio waste as well as rejects from the paper industry.

All materials contain valuable parts, e.g. copper, aluminum and iron, which are available and can again be sold as secondary raw materials when processed properly.

We offer tailor-made recycling solutions for your industry!

- WEEE and refrigerators

- Rejects from the pulp and paper industry

- Metals recycling and special processing

- End-of-life vehicles

- Waste to power - RDF plants

- Wood waste recycling

- Recycling of organic waste

- Plastic recycling

Contact to your Solution

Petra Wolf

Air pollution control

Wet flue gas cleaning, dry flue gas cleaning, DeNOx systems

Our products range from flue gas scrubbers for power stations to complex flue gas cleaning systems for Energy-from-Waste plants. Thanks to a wide product portfolio, innovativeness in engineering and long experience in executing projects, ANDRITZ has the right solution to meet all environmental and financial goals.

Products:

- Wet flue gas cleaning systems

- Dry flue gas cleaning

- DeNOx systems - Selective Catalytic Reduction (SCR)

- Combined/multi-stage flue gas cleaning systems

- Scrubbers for the maritime industry

Contact to your Solution

Petra Wolf