The ‘WattsOK?’ research project combines artificial intelligence, optical inspection and robotics to enable automated quality testing of used photovoltaic modules. Based on the test results, the system makes informed decisions about reuse or recycling with the aim of maximising the service life of the modules while increasing resource efficiency and sustainability in the photovoltaic sector.

Project partners:

- AIT Austrian Institute of Technology – coordination, high-performance surface inspection, AI decision-making processes, reuse strategies

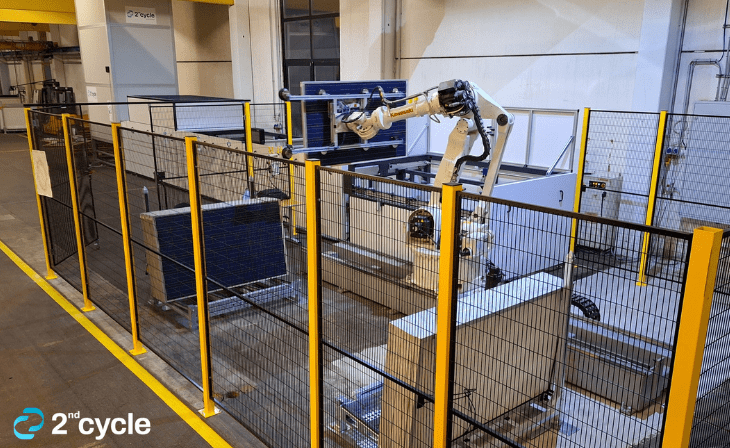

- 2nd Cycle FlexCo – multi-sensor reuse/recycling line

- PROFACTOR GmbH – robotics

- TÜV AUSTRIA HOLDING AG – development of scalable data structure and data fusion, AI decision-making processes

- Montanuniversität Leoben, Chair of Waste Utilisation Technology and Waste Management – life cycle assessment

- METRAN Rohstoff-Aufbereitungsgesellschaft m.b.H. – recycling strategies

The ‘WattsOK?’ project is funded by the Federal Ministry for Innovation, Mobility and Infrastructure (BMIMI) as part of the national FTI call for proposals on circular economy and production technology. It is being implemented by the Austrian Research Promotion Agency (FFG).

The rapid expansion of photovoltaic systems is a key factor in the energy transition – but it also brings new challenges. One of these is how to deal with millions of PV modules that will reach the end of their service life in the coming years. Currently, disused modules are usually recycled directly without first checking whether they are still usable. So far, there has been a lack of automated processes for making an objective decision. This is precisely where the new research project comes in, asking the question: ‘Watts OK? – can the module be reused or should it be recycled?’

With its official launch at the end of August, the ‘WattsOK?’ research project is starting its work, focusing on the reuse of PV modules with the help of robotics and artificial intelligence. The aim is to develop an automated decision-making process that determines the optimal recycling route for used PV modules: reuse or recycling.

‘With WattsOK?, we are developing an AI-based approach to the systematic reuse of photovoltaic modules – leveraging AIT’s strength in translating research into industrial solutions,’ explains Andreas Kugi, Scientific Director of the AIT Austrian Institute of Technology (AIT). The research project coordinated by AIT addresses the growing volume of used PV modules and lays the technological foundation for their systematic reuse. ‘With WattsOK?, we are creating a data-driven, automated solution to a real problem in the PV sector,’ explains Nicole Brosch, head of the project. ‘At the same time, it also shows how applied research can contribute to better resource utilisation in the spirit of the circular economy,’ adds her colleague Laurin Ginner. Both scientists conduct research at AIT in the field of high-performance optical inspection and image processing.

Smart decision-making process – what ‘WattsOK?’ does

At the heart of the project is an intelligent, automated decision-making process that determines which used PV modules deserve a second life and which actually need to be recycled.

It includes:AI-supported optical inspection procedures for testing surface quality, as well as

precise electrical measurements for testing functionality.

This process is supplemented by robot-assisted replacement of connectors – an initial refurbishment step that makes the modules ready for use again. A database that links inspection data, measured values and product specifications plays a central role in this process. This database not only serves as the basis for the AI algorithms, but also ensures transparency and traceability of decisions.

“With our system, we are first movers in the field of automated, economically viable testing of PV modules that is also suitable for larger quantities. WattsOK? uses the data from the tests. We – and therefore also our customers – benefit from the results of the research project. The project is a great example of how research and commercial use can be efficiently combined – to the benefit of all involved,” says Simon Prüller, CEO and co-founder of 2nd Cycle.

Success story: From pilot project in EDIH AI5Production to funded FFG project

The research project that has now been launched was preceded by a successful pilot project within the framework of the European Digital Innovation Hub (EDIH) AI5Production. In close cooperation between the AIT Centre for Vision, Automation & Control and the Lower Austrian green tech start-up 2nd Cycle FlexCo, initial innovative approaches to automated optical inspection of used PV modules were tested and validated as part of the ‘Test Before Invest’ initiative.

This preliminary project served as a feasibility study and laid the technological foundation for the scalable solution that has now been launched. WattsOK? builds directly on these findings and exemplifies how a low-threshold entry into digitalisation via the EDIH can become a fully-fledged, funded research project.

AI5Production – Digital booster for industry

AI5Production supports Austrian companies in their digital transformation with a focus on artificial intelligence, Industry 5.0, cybersecurity and digital production. With access to state-of-the-art infrastructure, consulting and test environments, the hub is the central point of contact for innovative developments. Now it’s time to move on to the next round.

Enquiries & Contact

Mag. Dr. Iman Kulitz, MA

Marketing and Communications

AIT Austrian Institute of Technology

Centre for Vision Automation & Control

Mobile +43 (0) 664 8890 4335

iman.kulitz@ait.ac.at I www.ait.ac.at

Daniel Pepl, MAS MBA

Corporate and Marketing Communications

AIT Austrian Institute of Technology

T +43 (0)50550-4040

daniel.pepl@ait.ac.at I www.ait.ac.at

[Source: OTS, AIT Austrian Institute of Technology, 28 August 2025]