Cattle Bedding material made of slurry with FAN BRU

The BRU concept (Bedding Recovery Unit) serves to separate, dry and hygienize the undigested fibres in the slurry giving rise to a cycle on the farm that results in cost reduction and the highest milk output.

The BRU concept developed by FAN Separator GmbH., a Bauer Group company, has been put into practice since 2005, and many installations are operating successfully to the highest satisfaction of their owners all over the world.

A heavy dairy cow needs to be bedded well. The choice of the appropriate bedding material is therefore not to be taken lightly. All materials have their advantages and disadvantages: Straw involves an unknown level of germ contamination and high storage costs. Sand is not very absorbent and causes heavy wear to machinery resulting in high expenses. Wood chips are rather expensive and not always available. All of these materials must also be transported to the farm first and then disposed of afterwards involving further expenses. Those who can afford them, still opt for the use of mattresses with the usual problems. BRU bedding material combines all advantages. BRU bedding is low-priced, fresh and available every day, highly absorbent, of a perfectly hygienic, constant quality and it is readily accepted by the cows.

It is worth taking a closer look at the BRU concept: The BRU is synonymous with recycling and producing fresh bedding material every day, directly on the farm. There is no need for additional storage space or reductions to the amount of solid matter in the slurry or overall slurry volume.

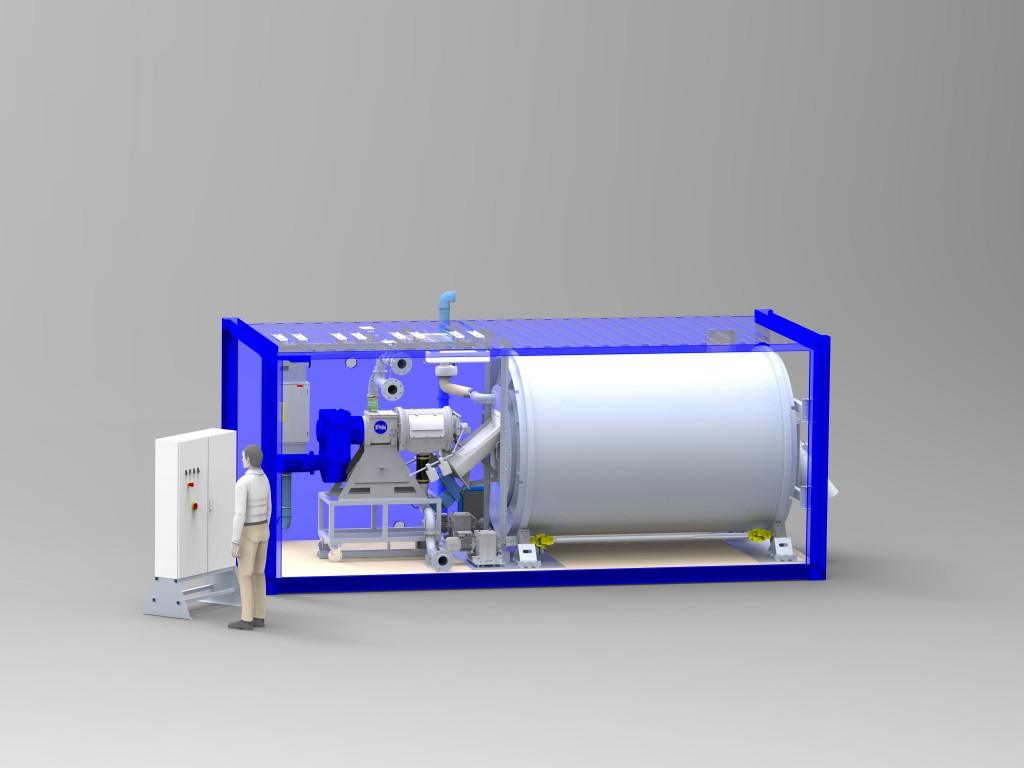

The slurry is first pumped from the collecting basin into the FAN press screw separator where the undigested fibres are separated from the raw manure. Then the material is fed into and transported through a 3 to 10 Meter long stainless steel drum (depending on the model) by means of a special patented conveying system.

It takes the material anywhere from 8 to 22 hours to pass through the drum. During this time, micro-organisms are acting on the material. Without any additional external energy, and through a natural, aerobic process, temperatures inside the stainless steel drum rise to more than 60°C to 75°C so that the material is not only dryer but also becomes hygienically perfect. The biological hygienisation process is a type of fast composting.

At temperatures of 60°C to 75°C inside the drum, almost 100 percent of all pathogenic germs which cause mastitis in dairy cows are destroyed. The inflammation of the udder involves huge economic damage to milk farmers again and again. Fresh, bio bedding material is one of the many prerequisites for high milk output.

The biological process inside the drum is monitored and controlled by means of temperature metering and the airflow rate. At the BRUs outlet, the material has a dry matter content of 40 to 42%. By means of conveying equipment, the bedding material is transported into an intermediate stock – 10 to 48 m³ of bedding material can be produced per day. With this amount of bedding material from 300 to 2.000 cows can comfortably be supplied.

Kowald Straße 2

8570 Voitsberg, Österreich

8570 Voitsberg, Österreich

Contact to your Solution

Hans-Peter Hojas

Produktmanager

Produktmanager