Circulyzer GmbH

Circulyzer GmbH is your competent partner in the development, planning and construction of plants for the wet-mechanical processing of waste fractions containing used plastics.

"If you take plastics and a water vortex, you get a simple and efficient way to separate them."

Simple but efficient - that is our motto.

Circulyzer GmbH is your competent partner in the development, planning and construction of plants for the wet-mechanical processing of waste fractions containing old plastics. The customised plant concepts enable an efficient recovery of the valuable material plastic for recycling.

As a spin-off of the University of Leoben, we have more than 10 years of experience in the research and analysis of various technologies for plastics separation. Our strengths lie in the conception of new process chains, as we do not shy away from breaking new ground without sacrificing the tried and tested. This is also reflected in our core technology, the centrifugal force separator (CFS), a cylindrical cyclone in which particle mixtures can be separated very efficiently according to their different densities in a swim-sink process. This was originally developed and operated for coal and mineral raw material processing. We have adapted and optimised this simple and robust device for the challenges of separating and recycling waste fractions containing old plastics. In combination with other units adapted according to customer requirements, we can process heterogeneous, more heavily contaminated waste fractions.

For example, the following product fractions are created with an upstream setting machine:

- a directly landfillable inert fraction (ceramics, glass, stones, etc.),

- a biogenically enriched substitute fuel and

- a highly concentrated polyolefin fraction (>90% PO content).

The latter PO concentrate is very well suited for the chemical recycling of plastics.

Furthermore, our innovative floating-sink separation unit can also replace existing separation/washing systems in the field of mechanical plastics recycling. This module impresses above all with its efficient separation of flat, but also very small particle collectives at high throughputs in a very compact design. This results in a cost advantage in operation for our customers.

At our test plant, we can evaluate very quickly and cost-effectively in which plant configuration and equipment a profitable separation of various input fractions is possible. If you have a residual fraction that still contains hidden potential for recyclable materials, or if you would like to recover more recyclable materials (especially plastics) from your existing material flows for recycling, then come to us and we will try it out together with you. We will be happy to make a proposal for the adaptation of your plant in order to increase the potential of plastics in your material flows.

In addition, we have been able to collect a lot of data from various processing units through our many years of research activities and tests. From this data, we have created a plant modelling tool, with which we can make a quantitative and qualitative statement about the material flows to be expected through the use of our plant concept proposal on the basis of the test results. Based on this, it is possible to estimate the expected investment costs and operating costs, of course taking into account your specific specifications and framework conditions. The evaluation of the feasibility and profitability of such a plant project is thus based on a solid foundation.

Circulyzer GmbH was founded by Dr. Markus Bauer and Dr. Daniel Schwabl, two process engineers specialising in plant engineering and secondary raw material processing. As you may have noticed, our approach to waste processing and plastics recycling focuses on efficiency. Through the eyes of a process engineer, the focus is always on the entire process within certain balance limits and especially on the interfaces to upstream or downstream activities. As a result, we also see ourselves as bridge builders from waste management to other industries, especially the oil, gas and petrochemical industries, especially with our previous focus on plastics.

If you would like to try something out, to go new ways without having to fear neglecting the tried and tested, then contact us. We are looking forward to your task and will try to find the most efficient solution for you!

Circulyzer GmbH

Peter Tunner-Straße 19

8700 Leoben, Österreich

8700 Leoben, Österreich

Your Contact

Markus Bauer

Geschäftsführer

Geschäftsführer

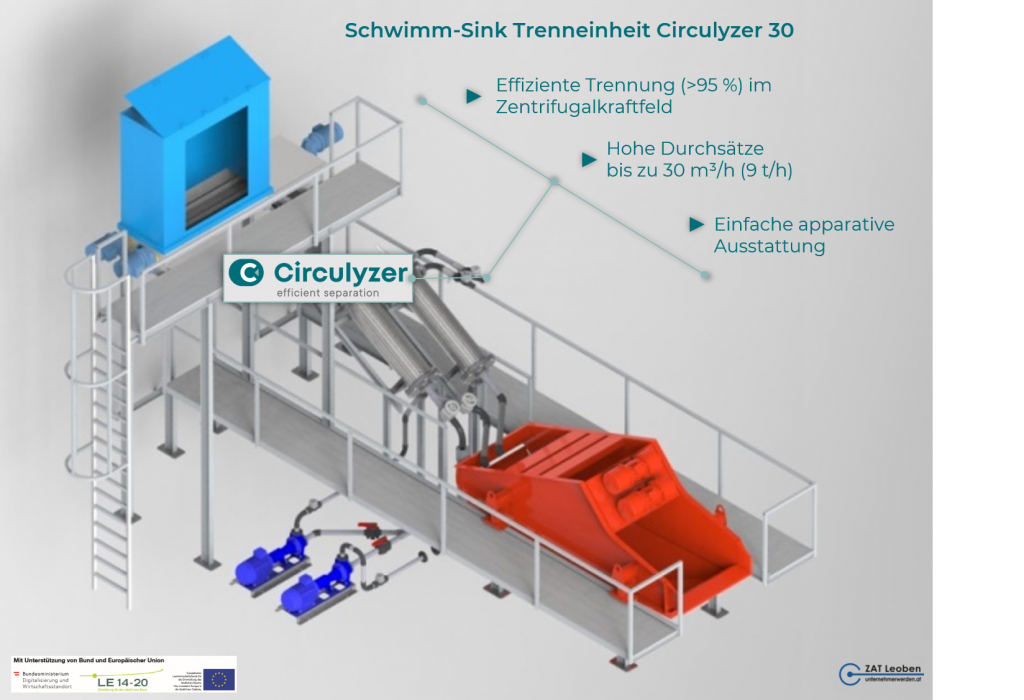

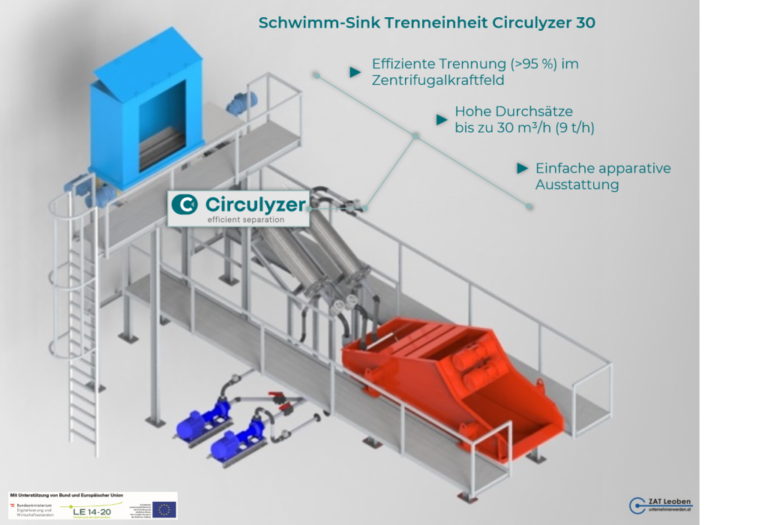

Sink-float separation unit Circulyzer 30

Take plastics and a water vortex and you have a simple, robust and efficient way to separate them

Sink- float separation unit to separate post-consumer plastics and/or waste fractions efficiently in the centrifugal field, while rendering high material throughputs and a compact construction

Contact to your Solution

Markus Bauer

Geschäftsführer

Geschäftsführer