R&D in the field of Sensor-based Sorting

Sensor-based sorting is used in waste management for sorting and analyzing waste streams and bulk materials. It is a non-contact process that offers a great deal of flexibility to cope with a wide variety of tasks.

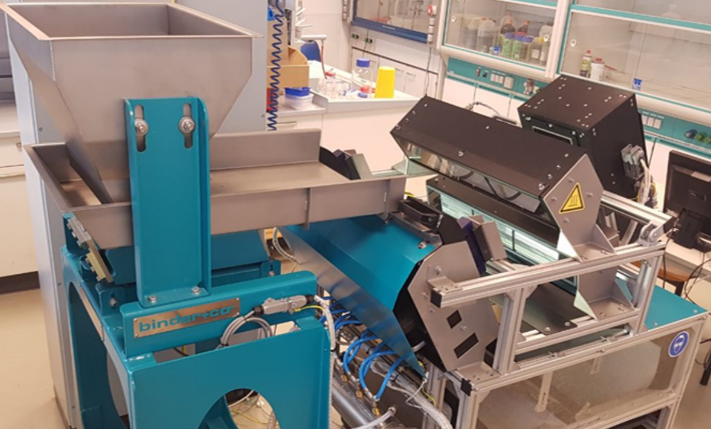

The Chair for Waste Processing Technology and Waste Management has an experimental sensor-based sorting setup for university and industrial research projects designed as a two-way machine. A grain size range from 5 to 300 mm can be processed. The feed takes place via a vibrating conveyor (1) followed by a glass chute (2).

The experimental sensor-based sorting setup contains three sensors that can be used for different waste streams:

– Near-infrared sensor (NIR) (5): waste glass, paper and cardboard, plastics, metals, and electronic scrap,

– High-resolution line scan camera (VIS) (5): plastics, wood, paper and cardboard, waste glass,

– Induction sensor (3): electrical conductors.

It is also possible to combine several sensors to solve very complex tasks.

Application example for NIR technology to sort PET bottles from a light packaging fraction:

Modern near-infrared sensors (NIR) (5) cover a wavelength range from around 1000 to 2500 nm. Halogen lamps, for example, can be used as emitters (4). As in the visible light (VIS) range, the radiation is selectively reflected by the objects examined and then measured by a detector (5). This spectrum contains information that allows conclusions to be drawn about the chemical composition of the investigated objects.

If packaging from the “PET” group is recognized, it must be separated from the rest of the lightweight packaging fraction according to the task at hand. The sorting is done using a compressed air blast. A valve bar (6) downstream of the sensor opens one or more valves when the PET packaging is in front of the valve bar. The PET packaging is “shot out” over the separating edge (7). All other types of plastic are deliberately not “shot out”.

Tasks and applications that have been worked on in research projects on the experimental sensor-based sorting setup:

– Sample characterization and determination of the composition,

– Creation of a digital grain size distribution,

– Discharge of contaminants,

– Enrichment of valuable substances,

– Sorting of bulk goods according to substance groups and

– Validation of sorting/separation results.

Processed waste streams on the experimental sensor-based sorting setup in research projects:

– Commercial waste,

– Landfill material,

– Products,

– Construction waste,

– Plastics,

– Compost,

– Substitute fuels,

– Waste glass and metals.

If you are interested in investigating your waste streams on the experimental sensor-based sorting setup, we will be happy to provide you with further information and advice.

8700 Leoben, Österreich

Sensor-based Sorting