IFE Aufbereitungstechnik GmbH

IFE is the only manufacturer to offer total solutions from the product areas of conveying, screening and magnet technology.

Machine technology developments and engineering were at the beginning of the company’s history.

Starting with the set-up of its own production department, IFE has developed steadily over the following years. The first products were

electromagnetic vibroconveyors. The high quality of the machines and the related economic success have made IFE a known producer in this field.

The product range has subsequently been enlarged by electromechanical vibroconveyors, screening machines and magnetic

separators. Today, innovative developments such as flip-flop screens, hard material separators and waste screens offer extensive package solutions for problems experienced in the field of material handling.

Representations:

In nearly all European states, Japan, Taiwan, Korea, China, South Africa, Australia, Canada, Brazil, etc.

“We see ourselves as a competent problem solver of our customers using vibrating and magnetic technology in various industries:

+ Waste and Recycling + Scrap + Sand and Gravel

+ Steel works and Smelting plants + Mines

+ Foundries + Slag + Coal + Feed

+ Chemicals and Plastics…”

“That’s what characterizes us. ”

Get practical IFE knowledge 4 times a year. Register here for our newsletter!

By loading the video, you agree to YouTube's privacy policy.

Learn more

IFE Aufbereitungstechnik GmbH

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

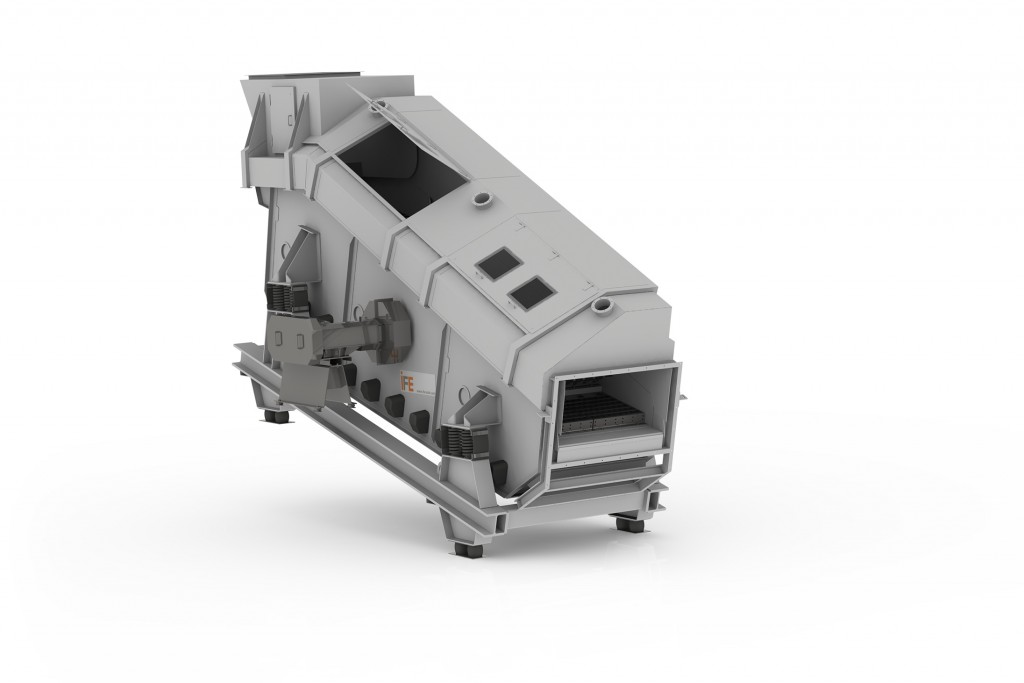

The flip-flop screen TRISOMAT is perfectly suited for difficult to handle material. These screens perform outstandingly where the decks of conventional screens clog or stick.

Advantages

• high specific feed rate

• unique 3-phase oscillation

• minimized clogging and sticking

• minimized dynamic loads

• maximized reliability

• mechanically strained screen mats

• feed material is accelerated to 50 g at the maximum

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

IFE eddy current separators are used to separate non-ferrous metals (aluminium, copper, brass, etc.) from bulk material of all kinds.

The centric design IFE INP is used to:

• removal of non-ferrous particles from

bulk streams (biomass, waste wood, etc.) • generation of non-ferrous concentrates(e.g. coarse material)

• separation of ubc (used beverage cans)

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

IFE-SORT is a density separator based on fluidbed technology for fine, dry material. This air sorting table uses a combination of vibration and airfluid technology to create the separation process. Heavier particles are conveyed against gravity, whereas lighter particles are floating on the fluidbed and slide downwards.

Applications include recycling and processing of secondary raw material. The SORT is also applicable in the wood, food and mining sectors for separation of dry materials.

Advantages

• all physical aspects are adjustable, providing a very wide range of applications, including very fine material

• high feed rates resulting in low operational cost

• maximized concentrations

• short payback

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

IFE magnetic drum separators are used to separate tramp iron from bulk material of all kind. Bulk material is fed via a chute or vibrating feeder to the separator and is conveyed by the roatation of the drum casing. Magnetic particles are attracted by the internal permanent magnet, whereas nonmagnetic particles follow their flight path determined by interia and gravity. The attracted material is conveyed by the drum shell to the end of the magnetic field and dropped to the other side of an adjustable splitter.

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

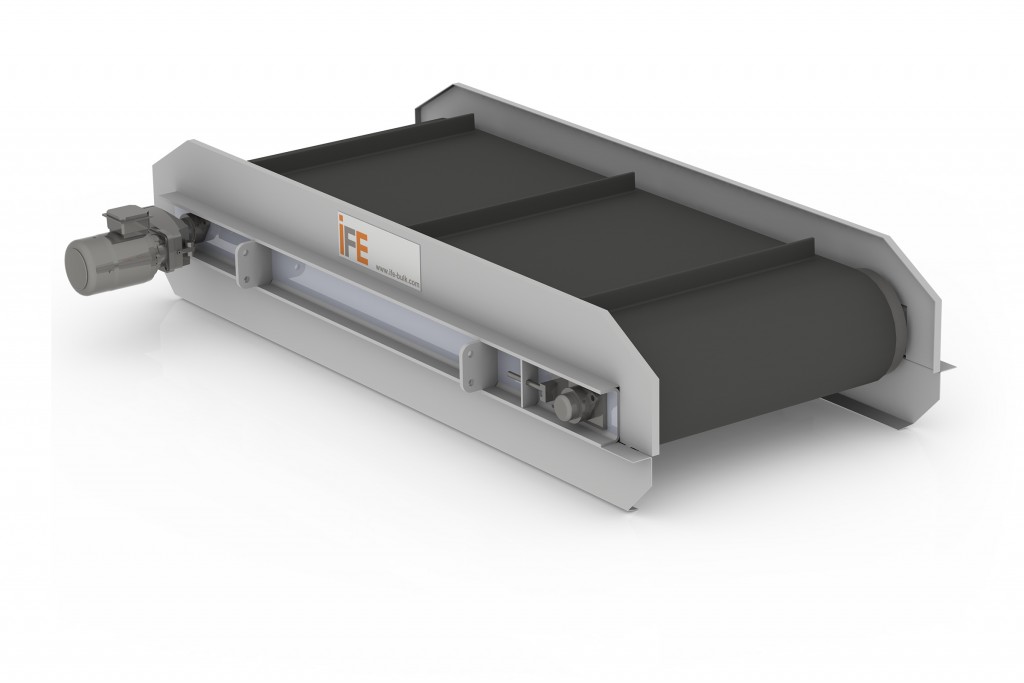

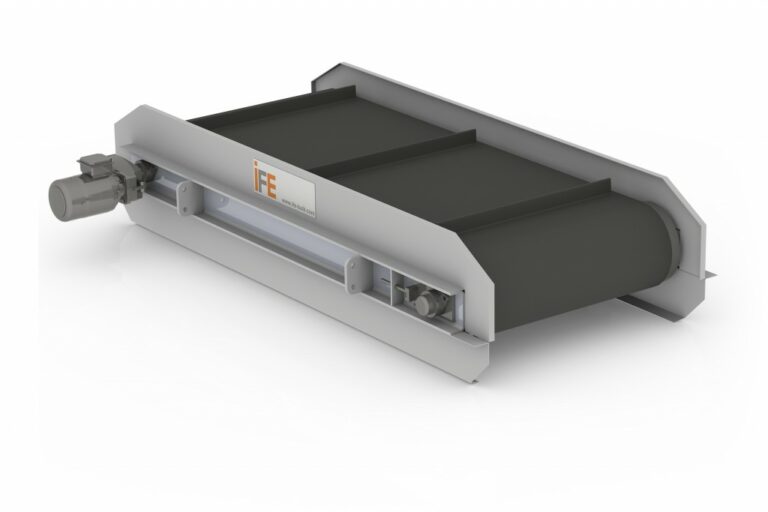

IFE permanentmagnetic overband separators are used to separate ferrous impurities from any kind of bulk material. They are used to recover magnetic particles from slag, household or industrial waste, foundry sand etc. and are utilized to protect crushers, belt conveyors, screens or grinders from metallic tramp particles.

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

IFE electromagnetic overband separators are used to separate ferrous impurities from any kind of bulk material. They are used to recover magnetic particles from slag, household or industrial waste, foundry sand etc. and are utilized to protect crushers, belt conveyors, screens or grinders from metallic tramp particles.

Most beneficial are electromagnetic overband separators, when strong magnetic fields are needed or arrangement of equipment only allows for high clearence distances.

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

IFE Hard particle separator and Destoner are used to concentrate valuable substances as well as to separate tramp material. Solid, heavy figures fall down, whereas flat, light particles are transported upwards by vibratory forces.

Typical applications can be found in recycling, glass, C&D waste as well as in the compost industry.

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing

The proven design of the upper deck combined with the new resonance system VARIOMAT of the lower deck provide for an extraordinary double deck screen. The screen is driven by the IFE unbalanced shaft and the flexible screen mats of the lower deck are agitated in resonance to the screen frame. This flip-flop design allows for non-clogging screenin

3340 Waidhofen an der Ybbs, Österreich

Leitung Vertrieb & Marketing